Cost Considerations

While the initial cost of EMS in Europe may appear higher than in Asia, the overall project expenses often turn out lower.

Reduced logistics costs, absence of import duties and access to local EU incentives make European manufacturing a cost-efficient and low-risk choice.

At SMD Baltic, customers benefit from predictable budgets, faster deliveries and reliable quality all within the European market.

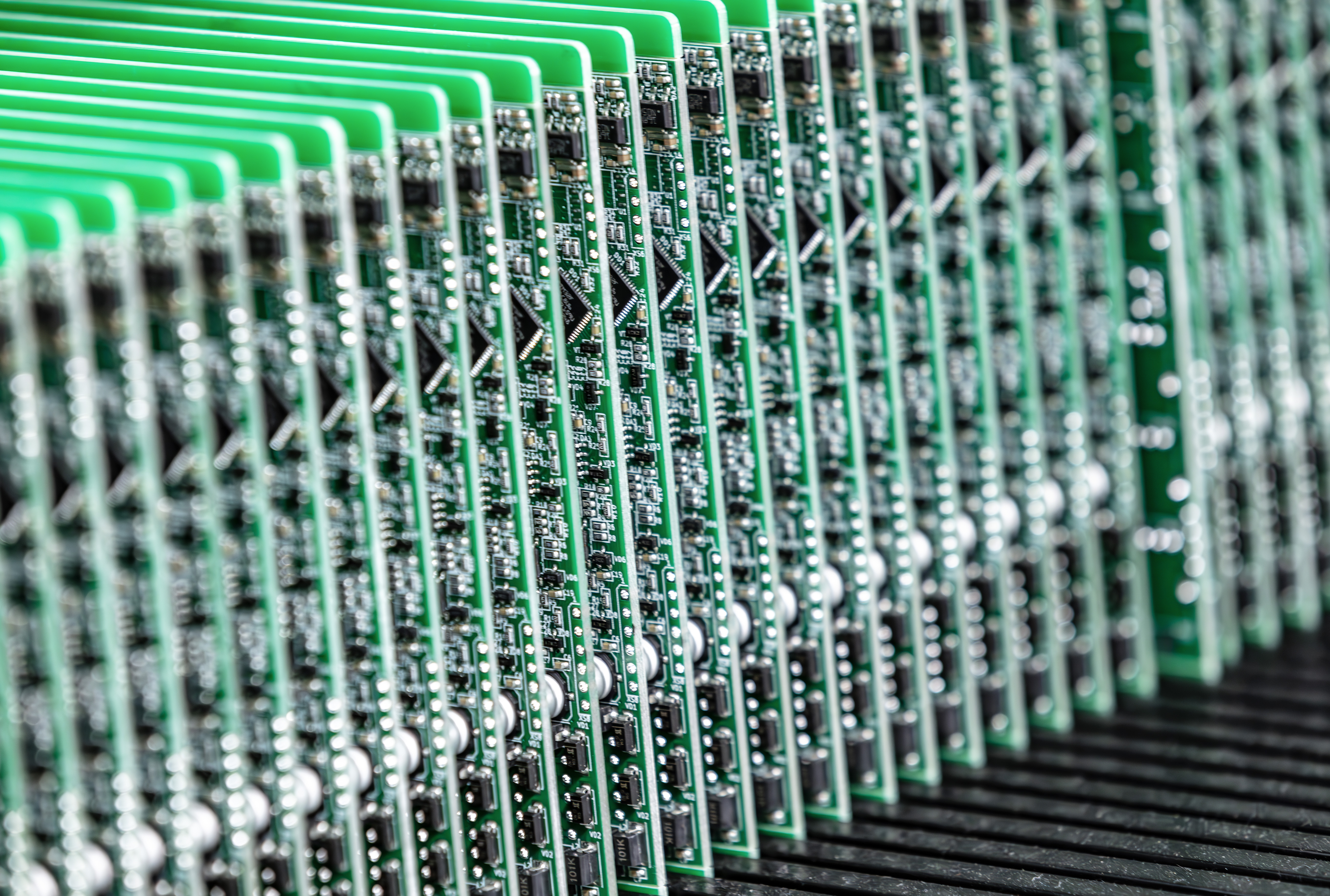

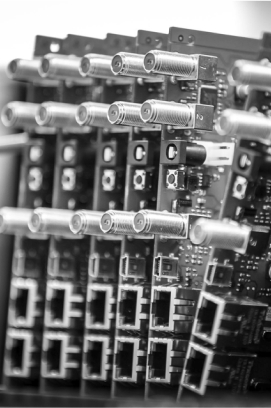

Quality Assurance

Compliance with EU standards – manufacturing aligned with strict EU regulations for safety, reliability and consistency.

Advanced technologies – modern equipment and optimized processes ensuring precision and durability of every assembly.

Skilled workforce – IPC-A-610 certified specialists applying Lean and Agile principles, supported by regular internal and external audits.

Automated Optical Inspection (AOI) – 100% of solder joints are visually verified to ensure flawless assembly quality.

Logistical Advantages

Logistics play a crucial role in the efficiency of EMS production, directly impacting delivery times, supply chain stability and overall project cost.

By choosing a European EMS partner, businesses gain shorter supply routes, predictable lead times and reliable infrastructure that minimize risks and ensure smooth project execution.

Typical delivery times from SMDbaltic:

| Destination | Standard (Global) | Express |

| Germany | 3-5 days | 1-2 days |

| United Kingdom | 4-7 days | 2-3 days |

| Finland | 2-4 days | 1-2 days |

Conclusion

Even the most complex PCBA can be produced in Europe with advanced technology, full quality control and reliable lead times.