Cost Considerations

Producing cable assemblies in-house eliminates the need to search for external suppliers or coordinate multiple contractors.

This saves time, reduces communication and logistics costs and ensures consistent quality and delivery control within a single production flow.

A streamlined process means lower overall project costs and faster time-to-market.

Quality Assurance

All cable assemblies undergo 100% visual and dimensional inspection, with X-ray analysis performed when required.

Since the assemblies are integrated into devices produced at the same facility, any feedback or corrective action is implemented immediately — ensuring consistent quality and reliability.

Logistical Advantages

Producing cable assemblies and final devices in one location eliminates extra transportation, packaging and coordination steps.

This integrated approach reduces logistics costs, shortens lead times and ensures smoother project flow.

Conclusion

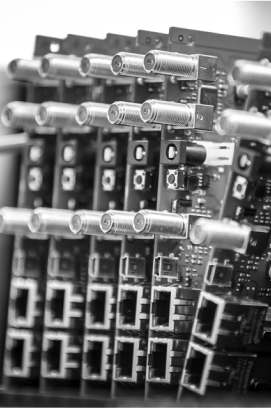

In-house cable assembly at SMD Baltic ensures seamless integration, consistent quality and full process control.

By combining precision manufacturing with efficient logistics, customers receive reliable connectivity solutions - faster, simpler and with optimized total cost.